Customised Fines Separation Unit for underground mine

A customised Fines Separation Unit for a mining client is working so well it is sending other units for modification. Its success means we have

Pneumatic industrial pumps designed for your industry.

Brain’s portable industrial pumps come in a range of sizes and are suitable for confined spaces or hard to reach areas. Choose from gravity discharge and pressure pumps,, self filling tankers, and vacuum recovery units. Use them for pumping in agriculture, mines, ships, rigs and sewers.

Our pumps are the original design – and the best. Made in Australia and built to last in the toughest conditions. They have no internal moving parts for better safety and reliability.

Brain’s pumps are used in Australia and around the world. We partner with Strata USA to distribute our pumps in the USA, Canada and South America.

Brain Airloader pneumatic industrial pumps handle just about any flowable material including sludge or slurries with solids to sand. Unlike conventional pumps, which rely on vacuum displacement, Brain Airloader compressed air pumps combine high velocity suction airflow with a powerful vacuum. The pumps come in a range of sizes to meet your needs.

We make both gravity discharge pumps and pressure discharge pumps.

Gravity discharge pumps are ideal when you wish to drop material into a nearby tank, container or other receptacle or on to a conveyor belt. You don’t want your materials coming out with great force.

Pressure discharge pumps help you to transfer or pneumatically convey material via pipe over larger distances.

We can also deliver pumps with DNV GL compliant frames. DNV GL certify compliance according to a third party standard, such as ISO 9001 (quality management system) or ISO 14001 (environmental management system).

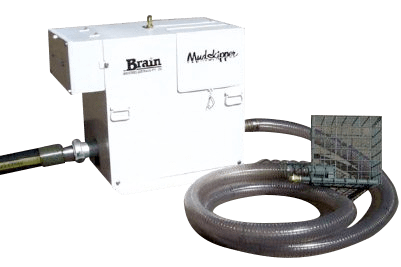

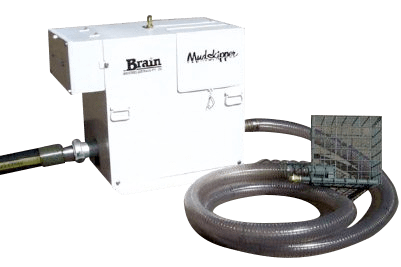

The Brain Mudskipper is our smallest and most popular pump. Use with the Mudskipper© Sieve Bend to continually separate solids while pumping.

Need a portable pump to easily vacuum and discharge sludges, slurries, and mud with solids up to 60mm?

Separate solids from sludge and slurry.

Use in conjunction with the Mudskipper Pump or we can customise to suit any of our Airloader pumps.

The bend removes the bulk of the water in the discharge feed from the pump. All solids larger than 0.4mm are returned onto the belt or collected for disposal. The underflow water exits by gravity or may be pumped away.

The bend can straddle a belt conveyor or be fixed to the roof in underground mines.

Recover, haul and dump heavily solids laden slurries and sludges containing lumps up to 150mm with Brain’s Self-Filling Tanker (also called a swilly buster or slurry tanker).

Skid-mounted or trailer-mounted to match your needs.

The trailer-mounted self-filling tanker is supplied with rocker arm load sharing swing axles, lubricated hubs and solid rubber tyres.

The tanker is powered by your site pneumatic system, making it perfect for the underground coal mining, hard rock mining, tunnelling and industrial cleaning industries.

Eliminate excessive air consumption and premature wear caused by dry running with the BrainAir-Operated Float Switch.

The switch ensures your pump operates only when it needs to, turning on and off automatically at pre-determined levels. It can handle level differentials from 125mm up to 3000mm and can be reverse operated.

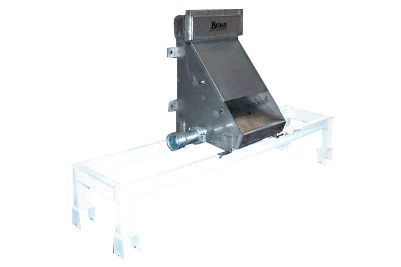

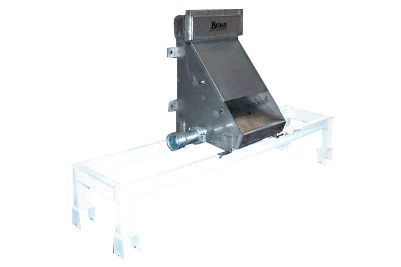

Brain Industries’ Fines Separation Units (FSU) dewater solids laden slurry or fines laden water from several sources simultaneously.

Brain’s FSU doesn’t just separate coal fines. It can dewater almost any hard ore, rock, stone, sand, or other contaminants and hazardous materials with a particle size of less than 80mm that are within water soluble clays or silts. Dewater up to 30,000 litres per hour and recover 40mᶟ of dry fines or other material every 24 hours. The end product has a typical moisture content of 15% – 20% and can be discharged directly on to a conveyor belt, hopper, or secondary dewatering screen.

The fully automatic slurry management system uses an auger to separate coal fines and other materials from water. The auger can be pneumatically, hydraulically, or electrically driven. The FSU is silent, uses little power, can be skid mounted and is easily transportable.

Better manage sludge and slurries with a Fines Separation unit from Brain Industries.

A customised Fines Separation Unit for a mining client is working so well it is sending other units for modification. Its success means we have

If you have water, sludge or slurry issues from rain and flodding that you need to fix now, hiring a Brain pump is the smart

Helping you in the big wet If you have water, sludge or slurry issues you need to fix now, hiring a Brain pump is the

After Hours

Nick (Production Manager)

M: +61 428 244 617

Tom (Lagging)

M: +61 421 845 737

Ernest (Sales Manager)

M: +61 429 916 097

Peter (Moda Marine)

M: +61 407 529 222

© Copyright [year] Brain Industries (International) Pty Ltd