Brainwaves No 21 – October 2020

We’re a finalist in the HMA Awards A credit to the genius team at Brain Industries, we’re a finalist in the 2020 Hunter Manufacturing Awards.

Brain Industries custom Australian made conveyor products include:

Belt conveyor products

Ceramic wear liners

Small conveyor belt dewatering systems – Fines Separation Units

Pulleys

Pulley Lagging

We manufacture a range of belt conveyor products.

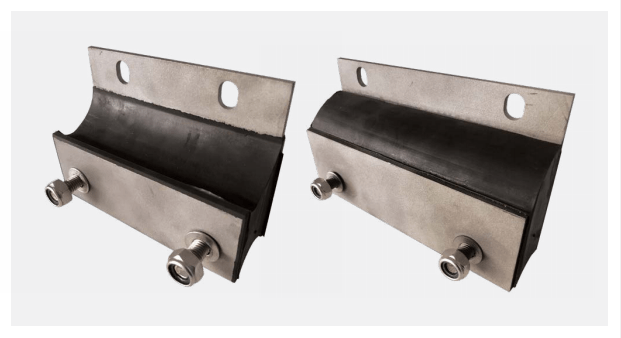

You need a clean conveyor belt to protect expensive conveyor systems. The best way to ensure full belt width cleaning is to use Brain Industries’ mounting cushions.

Often material fines cling to the conveyor belt past the unloading point. The residual material carries back on the return side of the conveyor leading to excessive wear on conveyor components, build up on return idlers, misalignment of the belt and adverse effects on the conveyor operation.

A conveyor belt cleaner removes material from the return side of the belt. Brain Industries’ stainless steel mounting cushions make sure your belt cleaner tips move independently and align to maintain the correct tip to belt pressure. This ensures your cleaner tips work properly even on belt surfaces that are worn or imperfect.

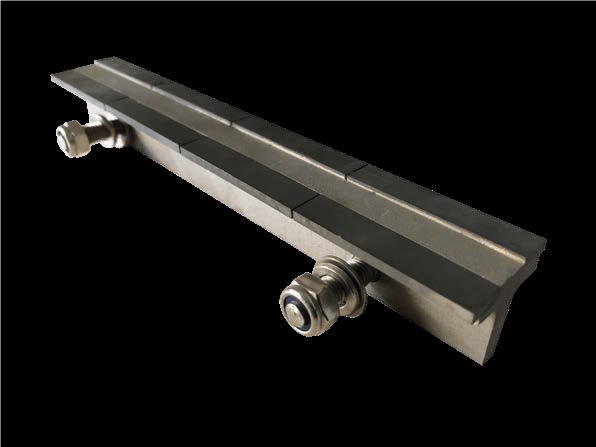

The other way to maximise the service life and effectiveness of your conveyor belt cleaners is to use Brain Industries’ Tungsten Carbide Tips.

Our Tungsten Carbide Tips are made using stainless steel to prevent corrosion. They provide high levels of resistance to abrasion and maximum resistance to carbide corrosion in environments with high acid or salt.

Brain Industries’ Tungsten Carbide Tips are designed for H, P and T belt cleaners used on sliced belts with good belt cover. Talk to us about solutions for belts with running mechanical fasteners.

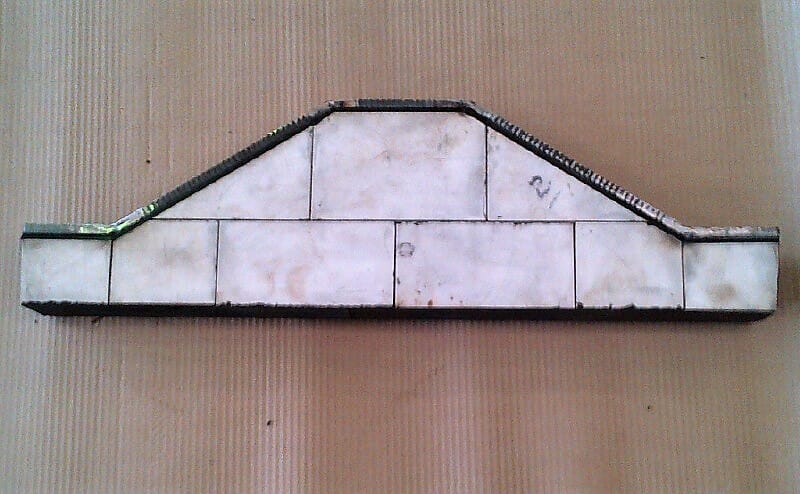

Reduce the cost of maintaining and replacing conveyor chutes. Brain Ceramic Wear Liners help make conveyor chutes and material transfer points last longer.

Also known as Protection Liners, wear liners are ceramic panels moulded to steel backing plates.

Key benefits of Brain Industries' dewatering units

Brain Industries’ Fines Separation Units (FSU) dewater solids laden slurry or fines laden water from several sources simultaneously.

Brain’s FSU doesn’t just separate coal fines. It can dewater almost any hard ore, rock, stone, sand, or other contaminants and hazardous materials with a particle size of less than 80mm that are within water soluble clays or silts. Dewater up to 30,000 litres per hour and recover 40mᶟ of dry fines or other material every 24 hours. The end product has a typical moisture content of 15% – 20% and can be discharged directly on to a conveyor belt, hopper, or secondary dewatering screen.

The fully automatic slurry management system uses an auger to separate coal fines and other materials from water. The auger can be pneumatically, hydraulically, or electrically driven. The FSU is silent, uses little power, can be skid mounted and is easily transportable.

Better manage sludge and slurries with a Fines Separation unit from Brain Industries.

What is pulley lagging?

Pulley lagging is a coating, cover or wearing surface applied to the shells of both drive pulleys and non-drive pulleys. The lagging protects the pulley shell (and can also protect conveyor belts) from abrasion. It extends the life of the pulley because the wearing surface (lagging) can be replaced for less cost than the pulley or conveyor belt. Lagging is also used to improve the friction between the belt and the pulley. Drive pulleys are often rubber lagged for this reason. Extend the life of your pulley.

Four types of Brain lagging in a range of sizes to suit your needs.

Correct design and installation of lagging is critical otherwise it can create more damage to pulleys. When using rubberbacked lagging the bond between the rubber and other substance (eg ceramic) is critical. Brain’s bonding strength is above industry standard.

We’re a finalist in the HMA Awards A credit to the genius team at Brain Industries, we’re a finalist in the 2020 Hunter Manufacturing Awards.

Brain Industries recent refurbishment of a deadshaft conveyor pulley for an Australian coal mine shows the importance of scheduled maintenance and the benefits of refurbishment

Industrial equipment manufacturer, Brain Industries, has promoted Tom Pattison to the new position of Product Manager, Conveyor Lagging. Managing Director, Gillian Summers, said the new

Custom made, quality, conveyor pulleys by Brain Industries makes materials handling easier.

Brain Industries' Conveyor Pulley Lagging bonds perfectly to the shell of your conveyor pulleys to extend the life of your pulleys and provide better grip to the conveyor.

Brain Industries’ Fines Separation Units (FSU) allow you to better manage sludge and slurries.

Brain Ceramic Wear Liners help make conveyor chutes and material transfer points last longer.

A clean conveyor belt is essential to protect one of your most expensive assets. The best way to ensure full belt width cleaning is to use Brain Mounting Cushions

After Hours

Nick (Production Manager)

M: +61 428 244 617

Tom (Lagging)

M: +61 421 845 737

Ernest (Sales Manager)

M: +61 429 916 097

Peter (Moda Marine)

M: +61 407 529 222

© Copyright [year] Brain Industries (International) Pty Ltd