In this issue

- Videos: Conveyor pulleys.

- Brainwave: Save $ by refurbishing pulleys.

- Polyurethane bumper bars – efficient, safe and durable.

- Air operated float switches reduce wear on pumps.

- Prevent carry back on conveyor belts – Poly vee return ploughs.

- Increase in pump hire.

Customised conveyor pulleys make materials handling easier

Our custom made conveyor pulleys make materials handling easier. Whether its a drive or non-drive or a deadshaft pulley, we’ll keep your conveyor belts moving efficiently.

We design and manufacture your pulley to guarantee reliability and performance. We use certified mild steel plate. Welds are ultrasonically and magnetic particle tested in accordance with Australian standards.

We also test, repair and refurbish pulleys.

Watch our other video on the benefits of Brain conveyor pulleys.

Watch our video on how we manufacture conveyor pulleys.

Download our conveyor pulleys brochure.

Save $ – Refurbish your pulley

Save time and money with our Pulley Refurbishment Service.

When overhauling your pulley our expert team will do non-destructive testing of the pulley shaft and shell and re-machine the pulley if it is required. With a complete strip down and cleaning of all parts and new lagging, your pulley will be good as new. As well as testing and certification, you’ll also receive supply of Manufacturer’s Data Reports.

We prepare a Refurbishment Viability Report with our quote. So, contact us today.

Brainwave! If you’re doing scheduled maintenance or a scheduled shutdown on your conveyor system, check if you need to refurbish or replace your pulley.

Polyurethane bumper bars improve safety & efficiency & last longer

Impact-resistant polyurethane bumper bars improve safety and operating efficiency. They also have a longer service life, and are up to 40% lighter than OEM design.

Prevent shock-related injuries to machine operators from minor collisions of machines during the loading process. Prevent unplanned machine shut-downs caused by “tripping” of sensors during minor impacts.

We manufacture FRAS polyurethane bumper bars for underground coal machinery such as continuous miners, shuttle cars, multi-bolters, man transporters, feeder breakers and dolly cars.

View all our Polyurethane products here.

Air-operated float switches reduce wear on pumps

Eliminate excessive air consumption and premature wear in pumps caused by dry running.

Eliminate excessive air consumption and premature wear in pumps caused by dry running.

Our Air-Operated Float Switch.ensures your pump operates only when needed. Your pump will turn on and off automatically at pre-determined levels. It handles level differentials from 125mm up to 3000mm and can be reverse operated.The twin float design delivers ultra reliable performance.

Download our Air-operated Float Switch brochure.

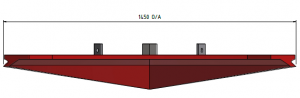

Prevent carry back on conveyor belts – Vee Return Ploughs

Vee return ploughs prevent carry back of coal slurry between a conveyor belt and the tail roller. Carry back is common if belt cleaners are not working as well as they should. The plough provides an additional measure and can eliminate the requirement for flat return rollers at the boot end.

Our FRAS polyurethane vee return ploughs come in various belt widths. There’s an optional stainless steel water spray system for dust suppression.

Read more about the quality of Brain’s polyurethane products here.

Increase in pump hire

Maybe it is the endless rain in Australia, but we’re getting an increase in pump hire orders. Smart customers want to save time and money – especially for a one-off clean up, dewatering need or slurry management issue.

As well as pumps, we hire our Vac packs, fines separation units, self filling tankers and stonedusters. You can buy after you have hired at a discounted rate. We deliver, and can set up and train your people to use the equipment efficiently and safely..

More information or to request a quote

To discuss your industrial equipment needs, contact the genius team at Brain Industries. We’re here to help.

Ph +61 2 4969 2111.

Email: admin@brainindustries.com.au