In this issue

- Video: Polyurethane products

- Customised poly solutions – protect and extend assets

- Case study – Custom polyurethane parts for shuttle cars

- Benefits of polyurethane lagging

- Polyurethane cable protection saves mines costly down time

- Polyurethane drift rope rollers for mines

- Walk for suicide prevention

Watch our polyurethane products video

Watch our video to see how polyurethane protects assets and people.

Customised polyurethane solutions protect and extend assets

More people from more industries are discovering the benefits of polyurethane coatings to protect and extend the life of equipment.

Our genius engineers custom design industrial polyurethane products to solve our customers’ problems and save them money in the long run. They can come to your workplace to assess and measure up.

Read how are team used polyurethane to extend the life of a clients vee belts.

We have our own in house equipment, manufacture most moulds in-house, and use premium polyurethane to ensure quality. Our four large polyurethane ovens mean we offer quick turnaround and our degassing equipment ensures the product is not porousdegassing/mixing equipment ensures an even component mix throughout the casting without air ingress… We can vary the polyurethane in terms of its hardness, elongation, tensile, and abrasion resistance.

We’re specialists in fire retardant and anti-static (FRAS) polyurethane products for the underground mining sector too.

See our polyurethane products and how they can help your business.

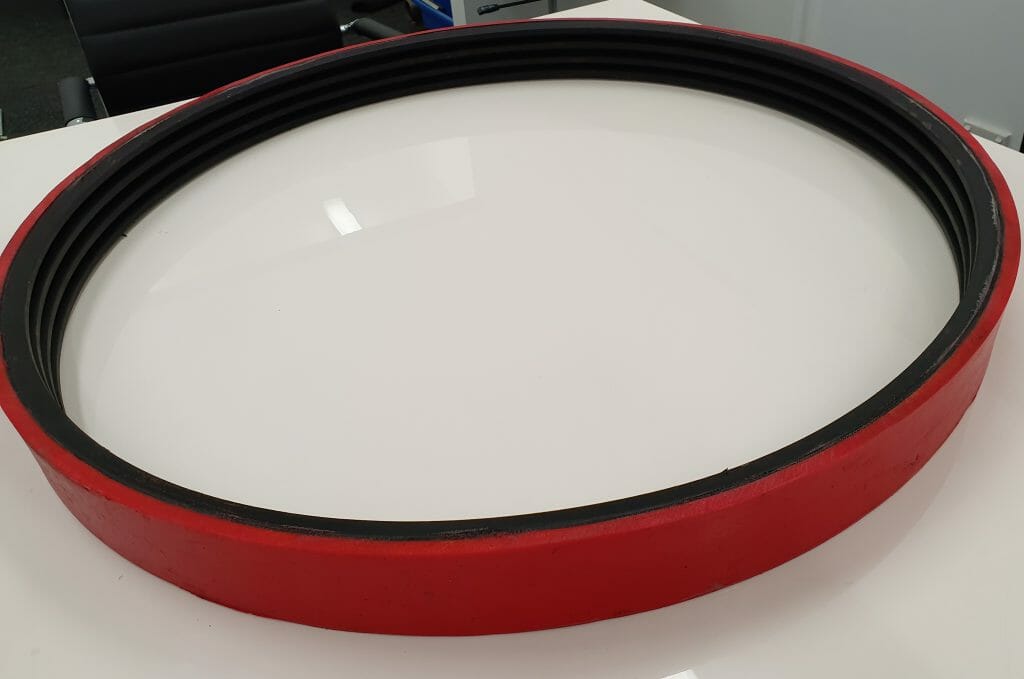

Case Study – Custom poly parts for shuttle cars

An Australian mining equipment manufacturer and overhauler has again come to Brain for custom polyurethane parts. We manufactured the following parts for four American designed shuttle cars it is assembling for its Australian client.

- Quick release bumper bars (pictured above in red)

- Back spool brackets

- Cable reel covers

- Outrigger cable sheaves (pictured below).

Our use of FRAS polyurethane means the parts comply with Australian Standard MDG 3608 for use in underground mines.

The benefits of polyurethane pulley lagging

Brain Industries is the only Australian manufacturer of polyurethane rubber backed lagging. It is often used for problem wear pulleys as well as non drive pulleys.

Polyurethane is low wearing so it lasts 5 times longer than traditional rubber lagging. Read our case study which shows how for one client poly rubber was 5 times cheaper over 10 years than rubber lagging. .

Hot cast polyurethane lagging has a higher level of bond strength and Total Indicator Runout (TIR). It provides good abrasion resistance and lasts up to 7 times longer than traditional rubber lagging.

View Brain’s full range of lagging products.

Did you know? As well as lagging, Brain also makes, repairs, maintains and certifies conveyor pulleys?

Click to watch our pulley lagging video

Polyurethane cable protection saves mines costly down time

Polyurethane protects shuttle car and continuous miner cables from costly damage. Repairing or replacing cables is expensive but it is also the down time that is costly. Cable damage is a reportable incident to both the NSW & QLD Mines Regulators.

Durable and flexible, polyurethane is perfect for the job. We can customise cable protection solutions for underground mines. We recently protected a high tension cable across a roadway. Trucks and other equipment don’t hit the cable which is strapped against the roof.

Polyurethane drift rope rollers for mines

Fire resistant and anti-static (FRAS) polyurethane drift rope rollers better protect the main haulage wire ropes on the drift in underground mines and on draglines that use rope haulage pulleys.

Polyurethane coated rollers last longer and offer better abrasion resistance. The polyurethane coating is light weight but strong for improved load bearing. It is durable and doesn’t rust.

Polyurethane protects machinery and components from heat, water, oxygen, oil and grease, chemicals, fire and flames, and mould to reduce risk and create a safer workplace.

Walk for suicide prevention

Our Managing Director Gillian Summers joined more than 500 others to take part in the Lifeline World Suicide Prevention Day Walk in Newcastle.

One of a number of dawn walks held around Australia, the purpose is to bring discussion about suicide prevention out of the shadows.

As a former Board member, CEO and Ambassador of Lifeline Hunter and Central Coast and some who has lost people close to her to suicide, Gillian is passionate about supporting good mental health in the workplace and community.

Read how Brain is also supporting another mental health initiative.

If this story causes issues for you or you or someone you know is in crisis you can call Lifeline on 13 11 14.

More information or to request a quote

To discuss any of your industrial equipment needs, call the genius team at Brain Industries on +61 2 4969 2111, email admin@brainindustries.com.au, or use our contact form.