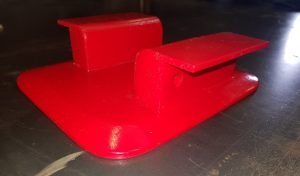

Leading longwall mines are turning to polyurethane coating of roof support lift key plugs, pontoon plugs and walkway plugs to improve safety and performance.

These plugs significantly reduce coal fines build up in tow holes. Coal fines build up can cause delays and additional work during longwall relocations.

Plugs are traditionally made from mild steel, making them heavy. Steel plugs can rust which makes them difficult to remove when relocating longwalls.

The benefits of polyurethane lift key plugs for mines

Brain Industries is supplying polyurethane coated plugs to longwall mines. This makes the plugs lighter and prevents corrosion.

Recently, we supplied a mine with lift key plugs fitted with rare earth magnets. The magnets fix the plug to a metal surface without needing to use mechanical fasteners, eliminating hot work.

The polyurethane coating provides excellent impact resistance and prevents the magnets from being damaged or shattering.

Other polyurethane coating of magnet applications in mines

Magnets can be coated in polyurethane to provide added safety and performance benefits for a range of mining components.

- Drill steel holders – for safe storage of steel drill holders on continuous miners.

- Dolly holders – for safe storage of dollys on continuous miners.

- Temporary roof supports – to hold the supports to mesh during installation.

- Non-slip roof support tread plates – to eliminate fasteners or retrofit to existing roof supports that do not have mechanical fasteners.

Other benefits of polyurethane for mines

There are endless polyurethane applications that can benefit mines at every stage of the mining process. From extraction to crushing, pumping, storage and transportation of coal and other minerals.

Polyurethane improves load bearing capacity, strength, as well as vibration, impact and abrasion resistance. It reduces wear and tear and prevents rust, extending the service life of mining machinery and components. Protecting machinery and components from heat, water, oxygen, oil and grease, chemicals, fire and flames and mould reduces risk and makes for a safer workplace.

Other popular polyurethane applications in mining include

- skirting

- pulley lagging

- pumps

- tread plates

- safety barriers

- bumper bars on shuttle cars and joy miners.

What other polyurethane mining products does Brain Industries’ make?

Our genius team are experts in using polyurethane in mining equipment for improved performance and safety.

Brain makes a range of standard polyurethane mining products and custom designs products to solve problems for mines. We specialise in fire retardant and anti-static (FRAS) polyurethane products for underground mines. Using our own polyurethane ovens, moulds and degassing equipment ensures quality control and faster turnaround times.

Visit our polurethane product page or call us today on +61 2 4969 2111. We’re ready to help.