In this issue

- New pulley lagging video

- Polyurethane longwall mine plugs

- How do you choose the most cost effective lagging?

- Brain recognised for manufacturing excellence

- Meet the team: Nick Jennings

New Video: Pulley lagging

You need conveyor pulley lagging that bonds perfectly to the shell of your conveyor pulleys to extend the life of your pulleys and provide better grip to the conveyor.

And some lagging option are better suited to certain applications. Brain manufactures a range of lagging – from rubber to ceramic and polyurethane – to meet your needs.

Our Australian made pulley lagging is made to last longer and comes in a range of sizes. We have lagging in stock or we can make your pulley lagging to order, with a fast turnaround time.

Watch our new lagging video here.

Find out more about our lagging options here.

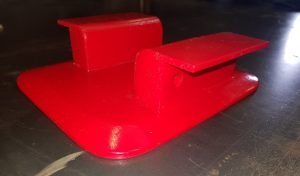

Polyurethane longwall mine plugs

Leading longwall mines are turning to polyurethane coating of roof support lift key plugs, pontoon plugs and walkway plugs to improve safety and performance.

These plugs significantly reduce coal fines build up in tow holes. Coal fines build up can cause delays and additional work during longwall relocations.

Plugs are traditionally made from mild steel, making them heavy. Steel plugs can rust which makes them difficult to remove when relocating longwalls.

Our polyurethane coated plugs are lighter and prevent corrosion.

View Brain’s full range of polyurethane products here.

How do you choose the most cost effective lagging?

There are different types of pulley lagging using different materials.

So, how do you assess which is the most cost effective pulley lagging option?

When comparing lagging options and pricing, make sure you are comparing apples with apples.

The quoted sheet price is one thing. but factors such as the sheet width (which influences the number of sheets you need) and the life expectancy of the lagging gives you a better guide to the overall lifecycle cost and its true cost effectiveness. The quality of the lagging varies too, depending on the manufacturer.

Read our case study and comparison blog here.

Brain recognised for manufacturing excellence

We’re a finalist for the second year running in the Hunter Manufacturing Awards. The accolades are a credit to our genius team and suppliers and partners.

Last year, Brain was highly commended in the Manufacturer of the Year category.

The awards showcase the strength and benefits of Australian manufacturing. This year’s winners will be announced on October 15.

Meet the team: Nick Jennings

Nick Jennings is our new Production Manager. He keeps things humming on the factory floor to get our quality products out to our customers.

How many years at Brain? 10 months

How many years working in manufacturing? More than 20 years in heavy engineering in the mining and energy industries

Best thing about your job? Working for an innovative “can do” company and the challenge of being able to satisfy customers product requirements and any special requests.

How do you like to relax outside of work? Cooking good food and binge watching crime show series.

More information or to request a quote

To discuss any of your industrial equipment needs, call the genius team at Brain Industries on +61 2 4969 2111, email admin@brainindustries.com.au, or use our contact form.