In this issue

- Videos: Visyload load detecting washer and Hydraguard oil diffuser system improve safety

- Underground mine’s pump problem solved

- Polyurethane tread plates

- Meet the team: Glen Marshall

Video: Visyload load detecting washers

Visyload is an Australian made, game changing, load detecting washer. It lets you know, at a glance, the working load limit on a rock bolt or threaded anchor.

This helps a mine, tunneling or construction manager or specialist Geotechnician to assess and certify – saving time and money.

Watch the video here.

Find out more here.

Control panel change maximises mine’s pump use

An underground mine had a Brain Airloader 300 pump but it wasn’t maximising its use. The control panel location made it hard to operate and difficult to maintain.

Our design and build team technicians moved the control panel to the discharge side allowing for ease of use. We also delivered hands on, on site, training on basic maintenance and operation to crews.

The pump is now in regular use pumping handling heavily solids laden slurries and sludges. The mine is also using it to clean up coal spills and carryback near the conveyor bootend.

View Brain’s full range of pumps.

Polyurethane tread plates

Our polyurethane non-slip tread plates can be used on longwall roof supports, continuous miner platforms, pump station walkways, feeder breaker walkways and more…to keep your staff safe in high traffic areas.

Polyurethane tread plates are resistant to impact, abrasion, chemicals, mine water, corrosion, and Solcenic fluid ingress.

We’re your experts in the design and manufacture of tread plates and other innovative polyurethane product solutions.

Read more about polyurethane products here.

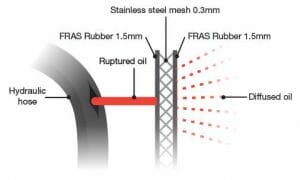

Video: Hydraguard prevents potentially fatal hydraulic hose rupture injuries

Do you have staff working around hydraulics on fixed or mobile plant?

Watch our video to see how our unique Hydraguard system protects them from potentially fatal pinhole ruptures of high pressure oil that can pierce PPE. Hydraguard’s rubber-encased, stainless-steel guarding system diffuses the oil through fine mesh to prevent injury.

Read more about Hydraguard here.

Meet the team: Glen Marshall

What do you do at Brain? Specialised fabrication on mining products

How many years at Brain? Five years with a break for health reasons

What do you like to do when not at work? Fish and hang out with my cockatiel (bird)

Something people don’t know about you? I left Brain because of ill health. My mates at work and the company made sure I was supported while away. I’m now back at Brain working full-time.

More information or to request a quote

To discuss any of your industrial equipment needs, call the genius team at Brain Industries on +61 2 4969 2111, email admin@brainindustries.com.au, or use our contact form.