Stone duster overhaul and pressure vessel inspection

Underground coal mining companies know of Brain Industries’ expertise in manufacturing stone dusters (rock dusters) but did you know Brain also inspects, services and repairs

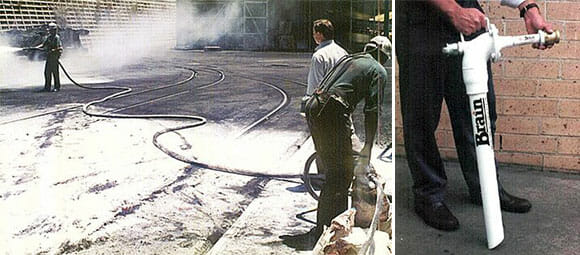

Rock dusters and stonedusters discharge stone dust to help underground mining companies meet their stonedusting program requirements.

Brain Industries’ stone dusters and rock dusters use our patented Mudskipper© jet pumps to deliver superior pumping power with minimal maintenance.

For our partner, Strata Worldwide, Brain designs, manufactures, and installs bulk stone dust delivery systems for underground coal mines, including 100-tonne to 200 tonne above ground silos for bulk storage.

We also deliver 3-tonne, 6-tonne, and 20-tonne dust to pit-bottom pressure-pods as well as 500kg to 1500kg dilute-phase tailgate dusting covering up to 4,000 metres (4 kms).

Designed for 25NB air supply, our Spear Duster will continuously discharge stone dust 30 metres or more via a 38NB stone dust hose delivering with good density.

The Brain Industries Spear-Duster has no moving parts and no electrics. It is intrinsically safe and constructed aluminium free to meet mining regulations.

Designed for 25NB air supply, it will continuously discharge stone dust 30 metres or more via a 38NB stone dust hose delivering with good density.

The Brain Industries Mini-Duster has no moving parts.

Our Maxi-Stoneduster has no moving parts and no electrics. It is intrinsically safe and constructed aluminium free to meet mining regulations.

The hopper has in excess of 15 bags capacity with a lid secured by chain to keep the contents dry.

The unit has a 25NB claw coupler for connection of the air supply hose and the air throughput can be controlled by regulating the air supply

ball valve.

Fluidising points in the hopper can be adjusted by regulating the fluidising air control valve.

Dust induction volume can be adjusted by rotating the stonedust volume control cone in the bottom of the hopper.

A 50NB brass male camlock is fitted for connection of the FRAS stonedust delivery hose which can be supplied with the unit if required.

The hopper is pre-filled with approximately 15 bags of stonedust and the 2” delivery hose positioned as required. It can be placed on the floor or passed through a stopping.

When the unit is activated it will steadily discharge the hopper contents over a 10-25 minute period before automatically shutting down. This steady metering of stonedust at high density into the ventilation air stream has been proven to achieve excellent coverage over long distances.

A 50NB stainless steel male camlock is fitted for connection of the FRAS stonedust delivery hose which can be supplied with the unit if required.

Underground coal mining companies know of Brain Industries’ expertise in manufacturing stone dusters (rock dusters) but did you know Brain also inspects, services and repairs

We’re a finalist in the HMA Awards A credit to the genius team at Brain Industries, we’re a finalist in the 2020 Hunter Manufacturing Awards.

There’s no wait on Brain’s pumps and stonedusters right now. The team at Brain have their proven, Australian made, pumps and accessories in stock, so

After Hours

Nick (Production Manager)

M: +61 428 244 617

Tom (Lagging)

M: +61 421 845 737

Ernest (Sales Manager)

M: +61 429 916 097

Peter (Moda Marine)

M: +61 407 529 222

© Copyright [year] Brain Industries (International) Pty Ltd