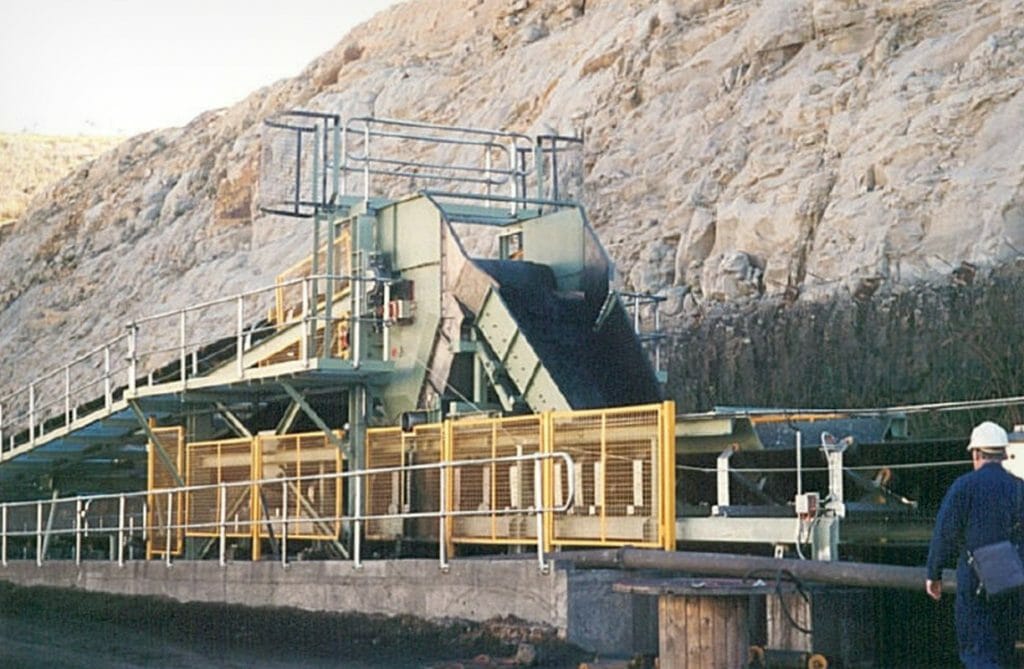

Belt Conveyor Dewatering Systems

The Conveyor Dewatering Systems effectively remove water from the coal stream on any mine site. The systems are highly customisable and are designed to suit the exact needs of each customer

Our belt conveyor dewatering systems prevent costly and potentially hazardous issues such as conveyor belts being over-run with water as well as water wrecking conveyor rollers.

Preventing drift conveyor spillage is an important work health and safety (WHS) measure.

In coal mines, conveyor dewatering systems remove water from the coal stream to improve coal quality.

When material has been transported any distance on a belt conveyor it starts to divide, with larger lump content moving to the top and the slimes and water to the bottom.

Key benefits of Brain Industries's Dewatering Systems

- Improve coal quality

- Remove excessive water on coal conveyors which results in material slough back and spillage on inclined belts.

- Retain discharge control by reducing water discharged into coal bins

- Control material movement on conveyors and from bins

- Improve productivity and profitability by reducing downtime, equipment damage, additional cleanups, corrosion and additional operation costs.

Special features of our Dewatering Systems include:

- Stainless steel wet areas

- Dewatering screen is not in the main flow, minimising screen impact damage

- Screen is reversible for increased life

- Main flow chute fitted with replaceable liners

- Scraper access platforms

- Allows passage of oversize lumps

Dewatering Screens & Underground Cyclonic Dewatering Systems

Our underground mine dewatering equipment eliminates excess water, particularly where it causes problems on steep drift conveyor belts or in underground storage bins. Our systems also remove solids from the water, so it can be handled by the mine’s regular water pump-out system without damage to pumps or pipelines.

Other Genius Conveyor Products from Brain Industries

Conveyor Pulleys

Custom made, quality, conveyor pulleys by Brain Industries makes materials handling easier.

Pulley Lagging

Brain Industries' Conveyor Pulley Lagging bonds perfectly to the shell of your conveyor pulleys to extend the life of your pulleys and provide better grip to the conveyor.

Dewatering Systems

The Conveyor Dewatering Systems effectively remove water from the coal stream on any mine site. The systems are highly customisable and are designed to suit the exact needs of each customer

Fines Separation Units (FSU)

Brain Industries’ Fines Separation Units (FSU) allow you to better manage sludge and slurries.

Ceramic Wear Liners

Brain Ceramic Wear Liners help make conveyor chutes and material transfer points last longer.

Mounting Cushions

A clean conveyor belt is essential to protect one of your most expensive assets. The best way to ensure full belt width cleaning is to use Brain Mounting Cushions