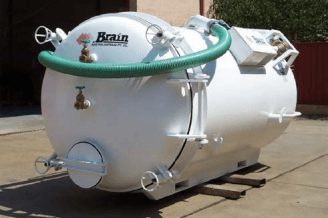

Self Filling Tanker for Vacuum Pumps

The 6 cu.mtr. capacity Brain Self Filling Tanker is a

transportable, intrinsically

safe, compressed air powered

unit for the vacuum recovery, haulage and dumping

of heavily

solids laden slurries and sludges containing

lumps up to 150mm in size.

Self filling tankers (swilly busters or slurry tankers) are used in underground coal and hard rock mining, tunnelling and contract cleaning services.

Available with MPV attachments, trailer mounted, or with fork lift sockets for loading onto a flat bed trailer or truck.

The powerful integrated compressed air operated jet pump is available in 300, 600 or 900 cfm capacities with vacuum capability of up to 27” Hg.

With no moving parts in contact with the material, continuous loading of large lump solids inclusions, waxy, fibrous and abrasive materials is possible without detriment to the pump.

Loading stops automatically at high level when handling wet materials. Excess water can be drained from the tailgate valves to allow top-up of load maximising hauled solids.

Slurries and flowable sludges can be emptied from the tailgate hatch. A full size side opening rear door and flushing attachment is provided for total clean out. Epoxy coated interior and exterior. Constructed aluminium free to comply with clause 39 coal mines regulations 1984.

| Loading Rate | Vertical Suction Lift |

|---|---|

| 1,200 litres/minute | Up to 30 metres. |

| Horizontal Suction Run | Air Consumption |

| Over 100 metres | Dependant upon jet-pump selection. |